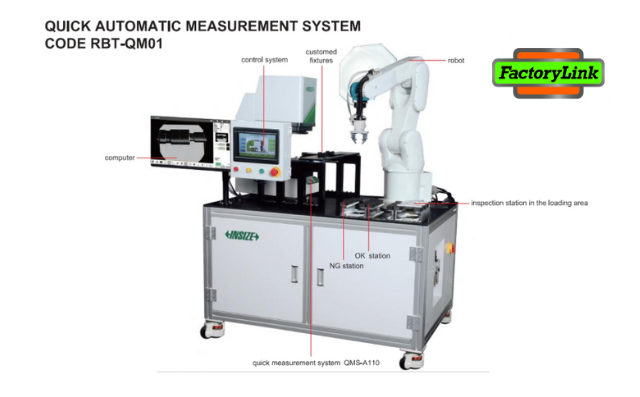

Insize RBT-QM01 robotic inspection

A Game-Changer in Robotic Inspection

In today's fast-paced manufacturing landscape, precision, speed, and reliability are essential. Enter the Insize RBT‑QM01, an Automatic Quick Measurement/Inspection System that stands out with its advanced robotics, rapid operation, and robust design. Let’s explore what makes this system a stand-out solution for modern quality control.

What Makes the RBT-QM01 Special?

- Rapid High-Throughput Inspection: The RBT‑QM01 automates measurement and inspection tasks, offering rapid throughput with consistent precision—a major upgrade from manual handling.

- Advanced 6-Axis Robotic Design: Featuring a six-axis robot mechanism, it delivers sophisticated motion control—ensuring flexibility and accuracy in acquiring measurements.

- Durable Industrial Protection: Built for harsh environments, the system incorporates IP67 protection—making it dust-tight and waterproof to withstand tough manufacturing conditions.

- Seamless Communication with Modbus TCP: Compatible with Modbus TCP, the system integrates smoothly into existing networks and industrial setups—boosting automation and data management.

Core Components

- Coaxial Lighting: Enhances visibility of features and surfaces during inspection—crucial for high-accuracy measurement.

- Optional Control System and Customized Fixtures: Tailor the system to your specific inspection tasks with configurable control setups and fixtures for varied parts.

- Integrated Quality Stations: The design includes OK and NG (not good) stations to automate sorting based on inspection outcomes—streamlining quality workflows.

Why the RBT-QM01 Stands Out

Speed & Consistency: High-volume inspections with precise repeatability

Flexibility: 6-axis robotic motion adapts to diverse inspection tasks

Durability: IP67-rated housing for operation in harsh industrial environments

Integration-Ready: Modbus TCP ensures fast, networked deployment

Customizable Setup: Tailors to different parts with fixtures and control options

Whether in automotive, aerospace, or precision engineering—if performance and uptime are critical, the RBT-QM01 excels.

Applications in the Real World

- Automotive Component Inspection: Quickly and reliably measure fasteners, bushings, or engine parts with repeatable precision.

- Electronics Fabrication QA: Non-contact inspection ensures delicate PCBs and components are checked efficiently without damage.

- Precision Parts Manufacturing: Supports tight tolerances and complex geometries—ideal for metal and plastic parts alike.

With its automated workflows and inspection stations, the RBT-QM01 minimizes downtime while maximizing throughput and quality. The Insize RBT-QM01 redefines robotic measurement and inspection with its blend of speed, adaptability, and resilience. Backed by advanced lighting, IP67-enclosed robotics, and network-ready controls, it's made to meet the demanding needs of modern production environments. If you're aiming to boost quality control efficiency and step toward smart manufacturing, the RBT-QM01 is a worthy investment.