FactoryLink Friday

In the world of precision manufacturing, accuracy isn’t optional — it’s everything. That’s why Factory Link Inc. is proud to feature INSIZE WiFi Digital Measurement Tools, designed to take inspection and data collection to the next level of connectivity, consistency, and control. Measure Smarter, Not Harder INSIZE’s WiFi Digital Measurement line brings the power of wireless technology directly to the shop floor. With instant data transfer via WiFi, machinists can capture, record, and share measurements without tangled cables or manual entry errors. From digital calipers and micrometers to height gauges and indicators, these tools seamlessly connect to PCs, tablets, or smartphones — allowing for real-time SPC data collection, remote monitoring, and streamlined reporting. Why It Matters In manufacturing, precision data drives quality. The INSIZE WiFi system eliminates the bottlenecks of manual logging, helping teams: 🔹 Improve inspection efficiency and traceability 🔹 Reduce human error in data collection 🔹 Enhance workflow visibility across the production line 🔹 Support Industry 4.0 integration and smart factory initiatives The Factory Link Inc. Advantage As a trusted distributor of INSIZE, Factory Link Inc. connects manufacturers with metrology solutions that fit both performance and budget goals. Our partnership ensures that customers have access to the latest digital measurement technologies, supported by local expertise and technical assistance. Whether you’re tracking part tolerances, performing QA checks, or upgrading to a smarter shop floor — INSIZE WiFi Digital Tools help bridge the gap between precision and productivity. LEARN HOW INSIZE CAN HELP YOUR SHOP

In manufacturing, partnerships matter just as much as products. At Factory Link Inc, we believe that our rolegoes far beyond simply taking an order or quoting a part number—we act as strategic allies, working side by side with you to solve real challenges on the shop floor. Why We’re Different We don’t just “sell.” We listen. Every recommendation we make—whether it’s tooling, workholding, metrology, or surface-finishing—is rooted in a deep understanding of your process. Our team brings technical expertise, application knowledge, and decades of combined industry experience to ensure you’re not just buying a product, but gaining a solution that saves time, reduces cost, and improves results. Solutions, Not Transactions When a cycle time needs to be cut, a new material presents machining difficulties, or quality demands push thelimits of inspection, you need more than a catalog. You need partners who understand the nuances of feeds, speeds, fixturing, coatings, and tolerances—and who can translate that into practical, actionable strategies. That’s where we come in. Building Long-Term Partnerships We measure success not in orders placed, but in problems solved. By collaborating closely with your engineers,machinists, and decision-makers, we help unlock hidden efficiencies, streamline operations, and keep your business competitive. Our goal is to earn your trust and become the first call you make when a challenge arises. Your Growth Is Our Mission Every manufacturer faces unique pressures—tight deadlines, evolving materials, workforce challenges, and costconstraints. At Factory Link Inc., we see ourselves as an extension of your team, committed to supporting your growth with proactive solutions, technical insight, and reliable service. Because at the end of the day, we’re not just sales people. We’re your strategic business allies. Talk to one of our sales representatives to learn how our unique approach can help you

As the year draws to a close, the team at Factory Link Inc. pauses to celebrate what makes our industry truly remarkable — the people, partnerships, and precision that drive American manufacturing forward every single day. This season, while many are wrapping gifts, we’re reminded that in our world, we wrap up projects. We finish builds, close orders, and prepare for a strong start to the new year — all fueled by the same dedication and craftsmanship that defines our customers and partners across the Midwest and beyond. At Factory Link Inc., we believe manufacturing is more than making parts — it’s about building opportunity . Every tool we supply, every spindle, vice, and cutting edge we deliver helps a shop reach new levels of productivity and performance. This year, we’ve been proud to strengthen our network alongside our principals continuing our mission to deliver solutions, not just products. As 2025 approaches, our commitment remains clear: Support our distributors and end users with fast, reliable service. Introduce innovative tooling and technology that push efficiency further. Foster growth and training across the manufacturing community. From our Factory Link Inc. family to yours — thank you for your trust, partnership, and shared drive for excellence. May your holidays be filled with peace, joy, and well-deserved rest. We look forward to an even stronger year of innovation and collaboration ahead. Merry Christmas and Happy New Year from all of us at FactoryLink Inc.

In today’s high-mix, high-precision manufacturing environment, speed and repeatability are everything. That’s why more and more shops are turning to 5th Axis Workholding solutions —a system built to maximize spindle uptime, reduce setup costs, and eliminate inefficiencies on the shop floor. At Factory Link Inc., we’re proud to represent 5th Axis and bring their cutting-edge RockLock bases, dovetail fixtures, and vises to Midwest manufacturers. Why 5th Axis? 5th Axis has redefined what “workholding” means for modern machining. Their system is designed around quick-change efficiency , allowing operators to go from job to job in seconds, not minutes. This is made possible through the RockLock zero-point system , which provides a universal interface for vises, dovetail fixtures, and custom applications. Key advantages: Repeatability within microns – ensuring consistency and reducing scrap Universal compatibility – mount parts, vises, or pallets across multiple machines Time savings – changeovers that once took 15–20 minutes now take less than 60 seconds The RockLock Advantage At the heart of the 5th Axis system is the RockLock Base Plate . With a simple quarter-turn, machinists can lock in workholding fixtures securely and repeatably. This means less time spent dialing in setups and more time cutting chips. Pairing RockLock bases with 5th Axis self-centering vises or dovetail fixtures makes it possible to grip even the smallest parts with absolute rigidity. Shops working in aerospace, medical, or high-value contract machining especially benefit from the ability to maximize every inch of their machining envelope. Learn how 5th Axis RockLock can help you

In a world where advanced machines, automation, and cutting-edge tools dominate the conversation, it’s easy to forget that manufacturing has always been — and will always remain — a people-driven industry. Precision is not only measured in microns or tolerances, but also in the care, dedication, and expertise that humans bring to the shop floor. At its core, manufacturing is about relationships: between operators and their tools, engineers and their designs, suppliers and their customers, and teams who rely on each other to deliver quality work every single day. While automation accelerates efficiency, it is human intuition, problem-solving, and creativity that drive real innovation. Think of a machinist who knows the “feel” of a cutting tool in a way no algorithm can measure, or a team that rallies together to solve a production challenge on a tight deadline. These human connections transform technical excellence into sustainable success. At Factory Link Inc., we believe that technology and people are not in competition — they are partners. The most sophisticated cutting tools, workholding systems, or metrology solutions achieve their true potential only in the hands of skilled professionals who understand how to unlock performance. As we continue to advance precision manufacturing, we remain committed to supporting not just the tools and processes, but also the people who bring them to life. Because in the end, precision is not just about parts — it’s about people. LEARN MORE

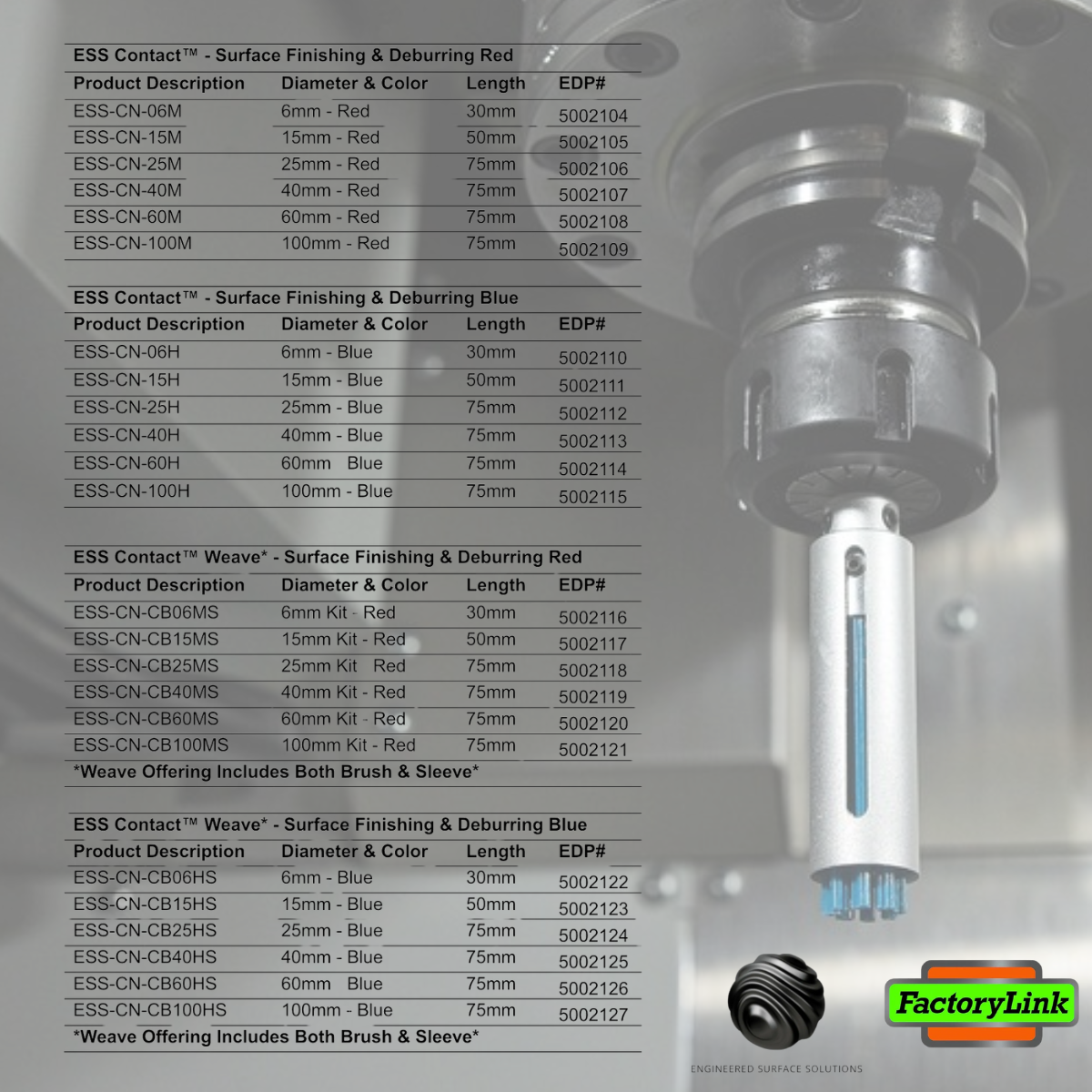

When it comes to industrial deburring, surface finishing, and high-precision internal tool solutions, E.S.S. (E SurfaceSolutions) remains the leader — and there’s only one official point of contact to get the real product, true specifications, and verified technical support. In manufacturing — especially when dealing with burr removal, tight tolerances, cross-section, or finishing tough materials — cut corners in communications or sourcing can introduce risk. A burr left behind isn’t just an aesthetic blemish — it can cause friction, premature wear, poor surface coatings, and even safety hazards. Using a single, verified contact prevents confusion and guarantees that you’re getting genuine E.S.S. solutions — with accurate specs, performance data, and support from the original source. What Sets ESS Apart E.S.S. specializes in mechanical and chemical surface enhancements , combining proprietary ceramic extruded fiber brush technology with deep-feature capability — ideal for challenging materials such as hardened steels (up to 70 HRC), stainless steels, super-alloys (Inconel®, Hastelloy®, Monel®, René alloys, Titanium), and more. Engineered fiber geometry delivers robust grinding power capable of removing burrs up to 0.010″ root thickness — and improves finishes while minimizing tool chatter and material stress. For surface-hole and deep-bore finishing, E.S.S. brushes outperform conventional media by “out-flexing” typical abrasive media while maintaining cutting pressure deep into features — reducing the need for manual “lollipop” tools or re-work. Compared to many incumbent solutions, E.S.S. often delivers 20–25% cost savings (due to longer tool life, faster cycle times, and reduced re-work), plus increased throughput and consistent part quality. For manufacturers looking for workflow improvement, reduced manual deburring, or precision-finished surfaces across aerospace, medical, firearms, automotive, or general machining — E.S.S. delivers tools built for accuracy, longevity, and repeatable results. As the Midwest representative, FactoryLink Inc. proudly supports E.S.S. with on-site demonstrations, product integration, training, and hands-on manufacturing solutions. If you need the right E.S.S. tool for your operation, Contact us FactoryLink Inc. for support. Either way — you’re connected to the same trusted network.