Sharon Cutwell - Driving Precision in Hydraulics

How Sharon-Cutwell Tooling Elevates Performance

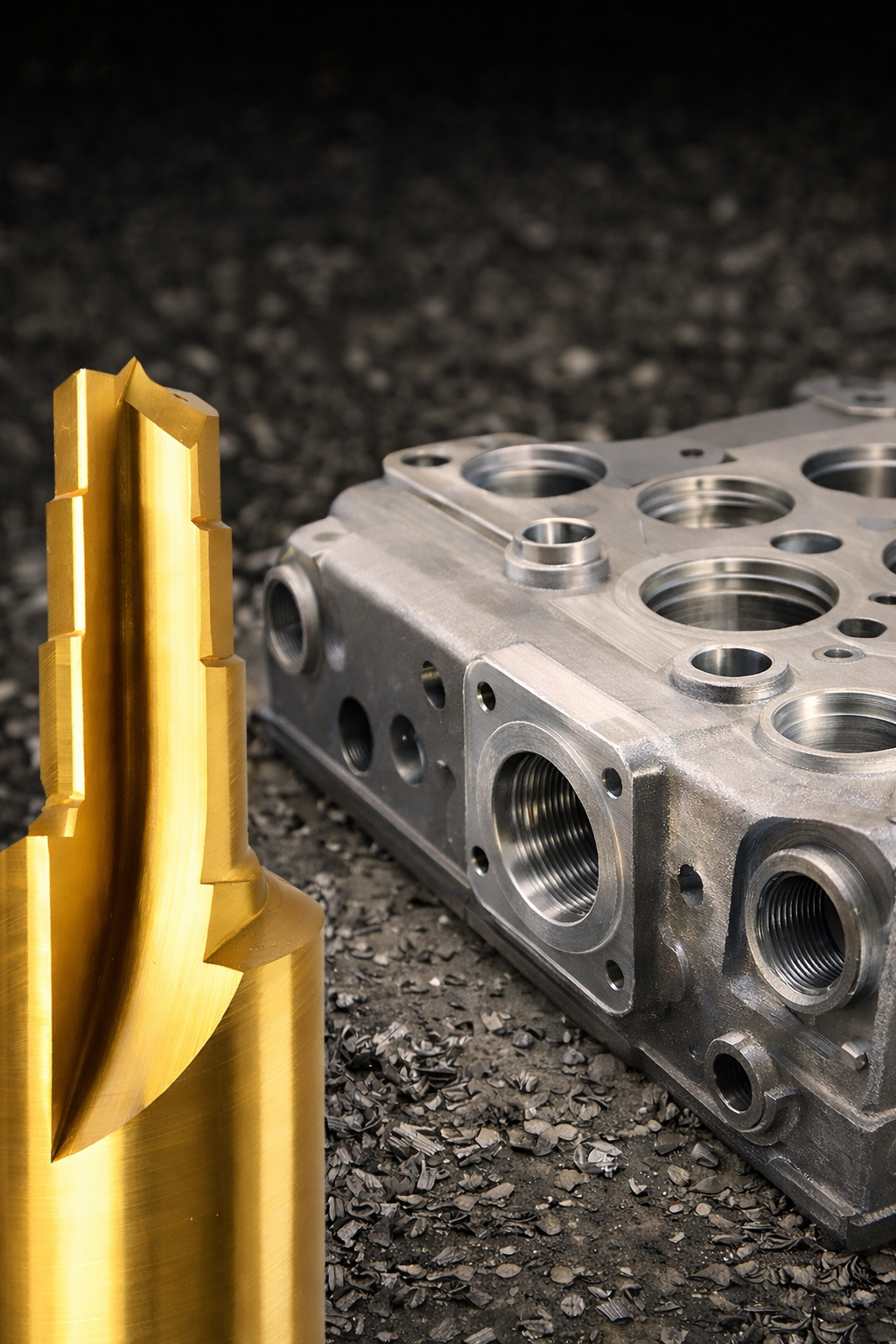

Manufacturers in the hydraulics industry face demanding requirements — extremely tight tolerances, smooth surface finishes, and highly repeatable processes. When your components are powering motion systems, fluid control valves, cylinders, and manifold assemblies, there’s very little room for error.

That’s where Sharon-Cutwell’s purpose-built tooling for hydraulics comes in. With engineered solutions tailored to hydraulic manifolds and flow paths, they help keep production efficient, cost-effective, and reliable. Below we dive into how their tools make the difference.

What is Hydraulic ?

Hydraulics power the backbone of modern industry — from construction equipment and aerospace systems to precision machining and manufacturing. By using pressurized fluid, hydraulic systems deliver the strength to lift, press, shape, and move with accuracy and repeatability. This is why precision tooling — like Sharon-Cutwell’s custom reamers, drills, and form cutters — is so essential: even the smallest imperfection in a hydraulic component can impact flow, pressure, and overall system performance.

Why Specialized Tools Matter in Hydraulic Manufacturing

Hydraulic systems rely on precisely machined internal passages, ports, and cavities through which fluid flows under high pressure. If manufacturing deviates even slightly—rough surfaces, dimensional error, or tool chatter—you can get:

- Pressure Loss

- Leakage

- Inconsistent Flow Dynamics

- Failures or Premature Wear

Therefore, tooling for this application must deliver both accuracy and finish, while being robust over long runs.

The Sharon-Cutwell Difference

Engineering & R&D Investment

Their in-house development ensures continuous improvements in tool geometries, coatings, and process knowledge.

Quality & Reliability

Their tools are built to deliver consistently across runs, minimizing downtime and rework.

Customer Service & Support

From quoting to design consultation, they emphasize helping clients manage custom tool inventories without disruptions.

Application Fit

Rather than a one-size-fits-all, they offer options tailored to the job: roughers, finishers, solid or brazed, optimized for different workpiece materials.

Specifying Hydraulic Tooling

To get the most out of these specialized tools, manufacturers ought to:

- Define functional tolerances clearly — which surfaces need tight tolerances, and which can be more relaxed

- Specify required surface finish (Ra, RMS) for flow-critical surfaces

- Communicate substrate materials (alloy, hardness, casting vs. bar)

- Share anticipated production volumes or run lengths

- Collaborate early with your tooling supplier in design and simulation stages

This level of transparency helps the tooling partner optimize geometry, coating, and machining strategy.

Learn how Sharon-Cutwell can optimise your workflow