GenSwiss Ti Loc Endmill Extensions

Unlock Precision in Swiss-Style Machining with GenSwiss Ti‑Loc Endmill Extensions

When it comes to micro machining, precision isn’t just a goal—it’s a requirement. That’s why GenSwiss developed the Ti‑Loc Endmill Extensions, part of their Signature Series of high-performance tooling engineered specifically for Swiss-type lathes and compact CNC platforms.

What Is Ti‑Loc?

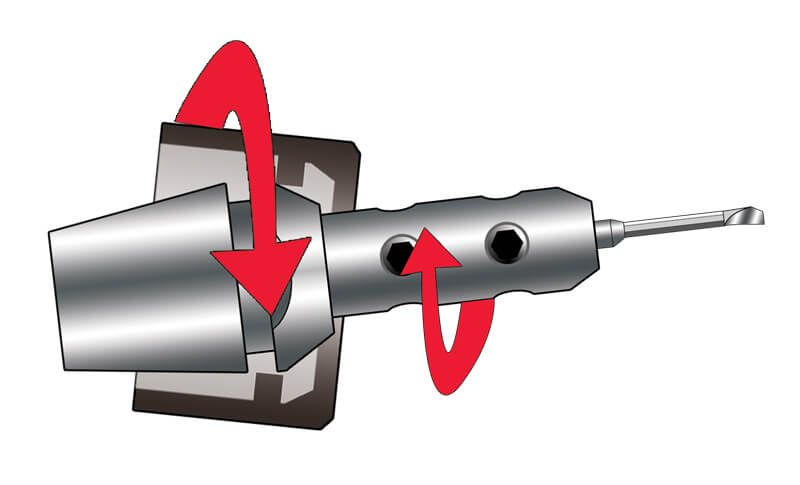

The Ti‑Loc is a taper-integrated one-piece extension holder that simplifies setups, improves rigidity, and enhances tool accuracy. Unlike traditional collet extensions that add layers of potential misalignment, Ti‑Loc integrates directly with the ER taper—resulting in a more rigid, reliable, and precise connection.

Key Benefits of Ti‑Loc Endmill Extensions

Ultra-High Accuracy

Ti‑Loc holders maintain

TIR (Total Indicator Runout) under 0.0002"—even when fully extended—ensuring tight tolerances and perfect tool path control in high-precision applications.

One-Piece Design for Superior Rigidity

Fewer components mean less tolerance stacking. The solid construction reduces vibration and deflection, extending tool life and improving surface finish on micro parts.

Quick & Easy Installation

These holders snap directly into standard ER collet nuts—no custom hardware or special tightening tools required. Spend less time setting up and more time cutting.

Coolant-Through Capability

Certain models (like ER16) are available with coolant-through functionality, providing enhanced chip evacuation and improved cooling at the cutting zone.

Flexible Range of Sizes

Available in

ER8 to ER25 configurations, Ti‑Loc extensions are adaptable to a wide range of micro tooling needs—including endmills, drills, and slitting saws.

Why Choose Ti‑Loc?

The GenSwiss Ti‑Loc system is purpose-built for demanding environments such as medical, aerospace, electronics, and precision automotive machining. Whether you're cutting titanium bone screws or miniature aerospace fasteners, Ti‑Loc empowers machinists to push further—literally—with minimal runout and rock-solid consistency.

Applications

- Micro endmilling in hard-to-reach areas

- Extended-reach slitting operations

- Deep pocket and cavity finishing

- High-precision Swiss-style turning centers

- Medical, aerospace, and high-tech part production

Experience the GenSwiss Difference

At FactoryLink, we’re proud to represent GenSwiss and their relentless pursuit of precision. If your team is looking to increase machining accuracy, reduce setup time, and expand micro tooling capability—the Ti‑Loc Endmill Extension is the solution you’ve been waiting for.

Contact us today to learn more or request a demo.