Why Manufacturer Representatives Are an Essential Piece of Your Company’s Success

Bridging Innovation and Industry with Trusted Expertise

In today’s competitive manufacturing landscape, companies are constantly searching for ways to grow sales, expand market presence, and strengthen customer relationships—all while managing leaner teams and tighter budgets. One of the most effective strategies for achieving this balance is working with manufacturer representatives.

Local Market Expertise

Manufacturer reps know their territories inside and out. They understand the customer base, industry clusters, and regional buying habits. This local insight allows them to match the right solutions with the right customers—faster and more effectively than a distant sales team could.

Cost-Effective Growth

Hiring and maintaining a large in-house sales team is expensive. Reps give you instant access to an experienced sales force without the overhead of salaries, benefits, and infrastructure. You gain reach and results while keeping your internal resources focused on core operations.

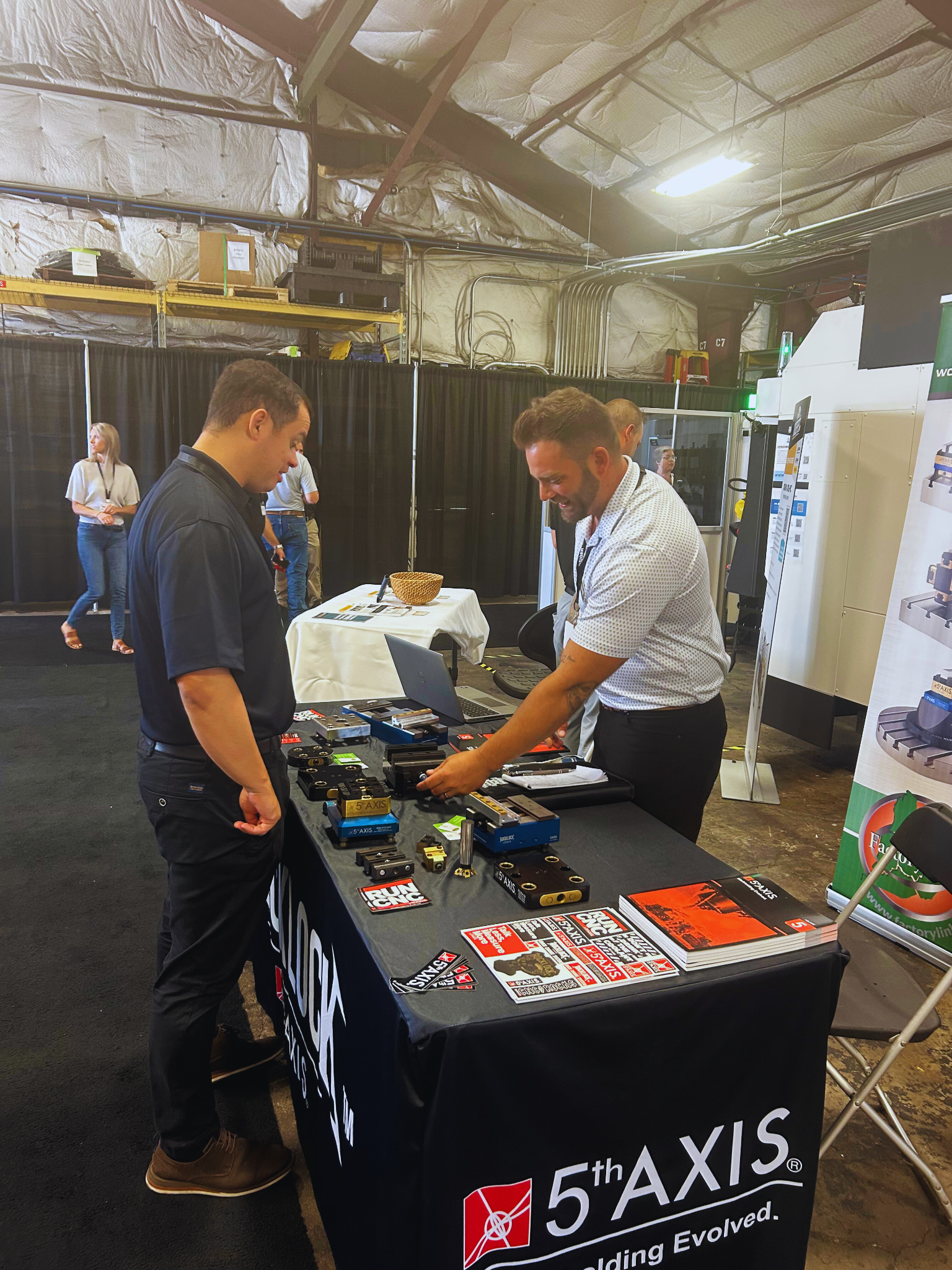

Strong Customer Relationships

Trust takes time to build. Manufacturer reps often have long-standing relationships with distributors, shops, and decision-makers in their regions. By partnering with reps, you’re tapping into networks that may have taken decades to establish.

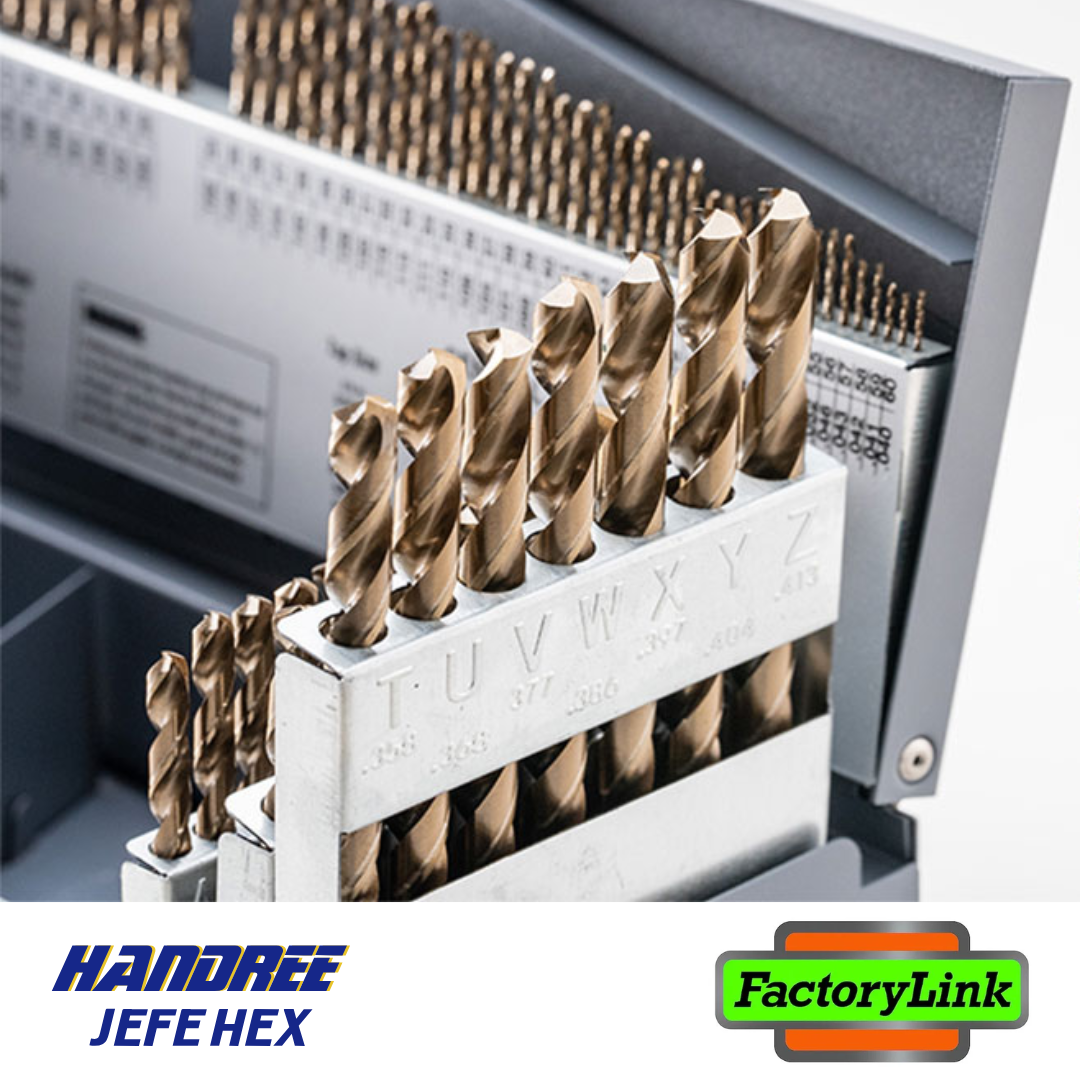

Technical Sales Knowledge

In industries like machining, tooling, and metrology, customers expect technical expertise. Manufacturer reps aren’t just salespeople—they’re problem-solvers. They can discuss applications, troubleshoot issues, and recommend products that fit the customer’s exact needs, giving your company credibility and added value.

Faster Market Feedback

Reps are on the front lines every day. They hear customer concerns, track competitor activity, and spot market shifts early. This real-time feedback loop helps your company adapt faster and stay ahead of the curve.

Focused Representation

Unlike a large distributor juggling countless lines, manufacturer reps typically represent a curated set of complementary brands. That means your product receives dedicated attention rather than getting lost in the shuffle. Why are manufacturing representatives a key piece of success for your company?

Hear it directly from our president, Keith Brown, as he explains how reps bring local insight, technical expertise, and trusted connections that make a difference.

Click here to watch