What Are 5th Axis Tombstones?

Keith Brown • June 27, 2025

Maximize Your Machine. Minimize Downtime

What Are 5th Axis Tombstones?

Tombstones are precision-machined structures that allow multiple parts or vises to be mounted vertically, increasing machine spindle access and maximizing part density. Designed for horizontal and vertical machining centers, they are a core part of high-volume and high-precision production setups.

Features

- Optimized for 5-Axis Access: Designed to reduce setup changes by enabling multiple workpiece orientations in one cycle.

- Multiple Mounting Surfaces: Typically, 2, 4, or 6 sides depending on the tombstone design.

- Rock-Solid Construction: Aluminum or steel bases with hardened steel locating features for repeatability.

- Modular Compatibility: Compatible with 5th Axis dovetail fixtures, vises, and RockLock quick-change systems.

- Custom Heights & Sizes: Available in a variety of configurations to suit machine envelope and part size.

Benefits in Production

- Reduce Downtime: Load/unload outside the machine with quick-change capability.

- Increase Throughput: Machine more parts per cycle, less manual intervention.

- Improve Accuracy: Single setup for multi-face machining reduces cumulative error.

- Scalable: Stackable or swappable fixtures for job flexibility.

Popular 5th Axis Tombstone Models

- TR Series (Rotary Ready): For direct mounting on rotary tables.

- TS Series (Static Tombstones): For vertical mounting on machine tables.

- RockLock-Ready Tombstones: Quick-change integrated.

Contact one of our Regional Managers for more information!

Engineered Surface Solutions (ESS) As manufacturers push toward higher accuracy, tighter tolerances, and automated workflows, deburring and surface finishing tools are expected to deliver more consistency, cleaner edges, and zero dimensional drift . Engineered Surface Solutions (ESS) was developed to meet exactly that demand. ESS introduces a full suite of next-generation finishing tools designed for CNC machines, robotic cells, high-volume automated systems, and precision hand-finishing environments . Built on extruded ceramic-fiber technology, ESS products offer controlled cutting action, long life, repeatability, and minimal surface damage . Below is an overview of every product in the ESS lineup—and how each tool improves manufacturing quality, efficiency, and edge integrity. Why ESS Tools Outperform Across all product categories, ESS shares a consistent foundation: ✔ Extruded Ceramic-Fiber Technology ESS uses rigid ceramic-fiber filaments that maintain shape and cutting pressure. ✔ Consistent Micro-Cutting Action Every fiber tip carries thousands of sharp cutting points, ensuring precision-level material removal. ✔ No Dimensional Damage ESS tools remove burrs— not metal —making them ideal for aerospace, medical, automotive, and hydraulic components. ✔ Automation-Friendly Designed for CNC programming, robotic arms, drill presses, and high-volume finishing cells. ✔ Long Life & High Productivity The fiber structure resists deformation and provides long-lasting performance even in automated cycles. Conclusion ESS brings a complete line of advanced deburring and finishing tools designed for tolerance-critical applications and automated machining environments . Whether you’re working in aerospace, medical device manufacturing, automotive machining, hydraulics, or high-precision metalworking , ESS provides the tools to: Eliminate burrs Maintain surface integrity Reduce manual finishing Improve throughput Support automated workflows FactoryLink is proud to support the introduction, distribution, and technical integration of ESS tools throughout the manufacturing industry. Fine out More

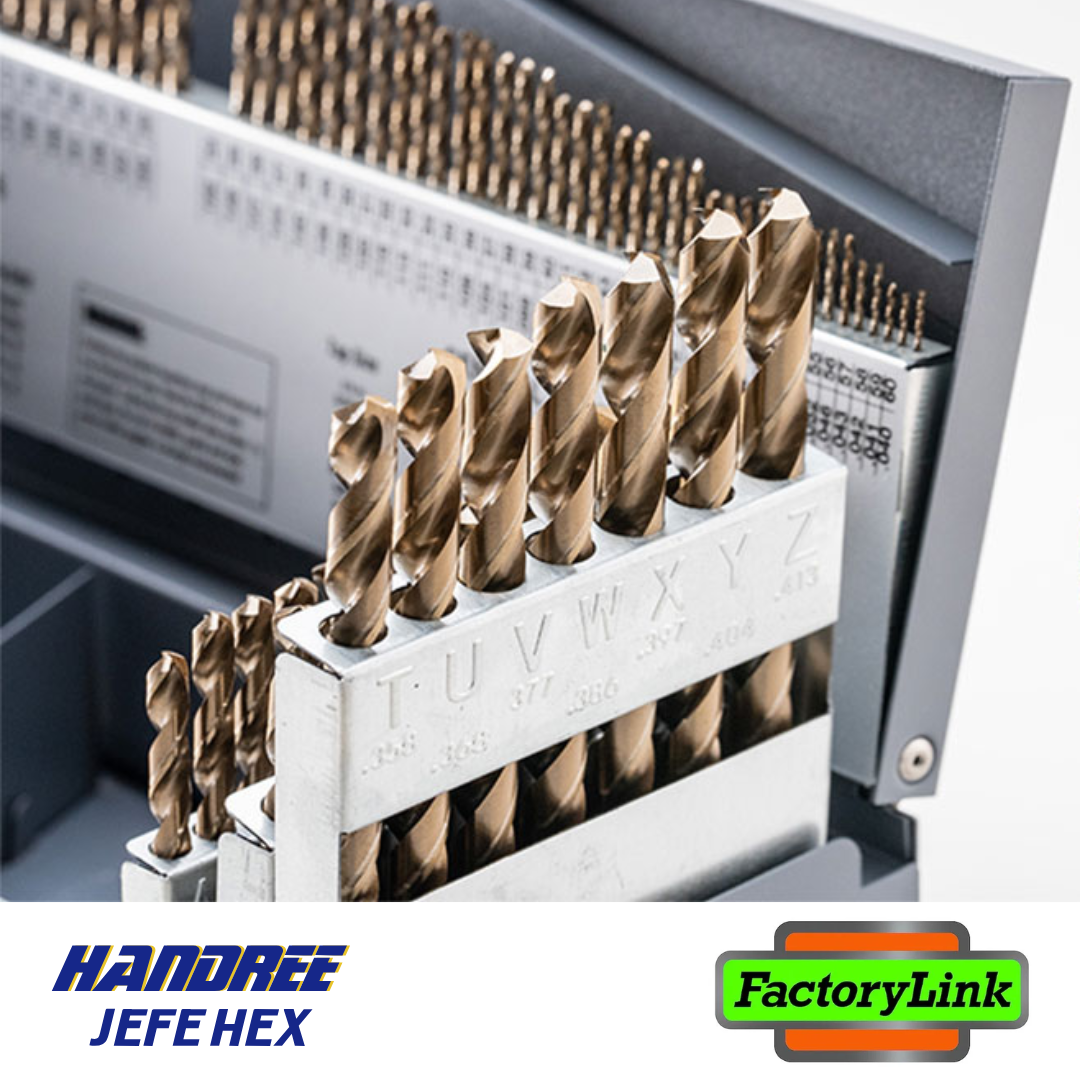

At Factory Link Inc., our mission has always been to deliver cutting‐edge solutions for manufacturing productivity and product quality. Today we’re excited to announce a strategic enhancement of that focus: we’re proud to introduce Handree JEFE HEX, a brand specializing in high-performance hole-making and drilling tools, as new principal with Factory Link Inc. Handree JEFE HEX brings a fresh dimension to our offering. Their product portfolio, featured at jefehex.com, demonstrates strong commitment to innovative design, quality materials and performance in demanding applications. By adding Handree JEFE HEX to our stable of manufacturers and brands, we expand the choice, flexibility and value we can bring to our distributor partners and end-users in the Midwest manufacturing market. What Handree JEFE HEX adds to Factory Link Inc. value proposition: Holemaking & drilling solutions – JEFE HEX offers sets and systems that align with current production demands, enabling more efficient processes. Innovative features – For example, their “Hex Shank Drill & Tap Set” is designed for paired drilling and tapping with matching sizes, simplifying workflow. Complementary fit – Our core markets (cutting tools, abrasives, metrology, work-holding) benefit when drilling/hole-making tools are included. This brand strengthens our end-user focus of solving productivity & quality problems. What this means for our partners For Distributor Partners: You now have access to a new, well-positioned brand with features suited to current manufacturing trends (e.g., hex shank systems, jobber length sets). For End Users: Whether you are in aerospace, defense, medical, appliance or general industry (segments we serve) you’ll have enhanced tool options under one go-to rep organization. For Factory Link Inc. Team: We’ll be incorporating Handree JEFE HEX into our training, marketing and technical support activities so our field team is fully equipped to assist with applications, cut-cost/raise-quality conversations, and inventory decisions. A bit of background Factory Link Inc. has been “linking” industry since 1987, with a base in the Midwest manufacturing community and a focus on the industrial supply channel. Our values—trust, expertise, efficiency—are at the core of everything we do. Handree JEFE HEX, via their online presence, showcases their commitment to performance, with product sets and descriptions that appeal to manufacturing professionals who demand durability and reliability. At Factory Link Inc., we believe manufacturing is more than moving metal—it’s about delivering process improvements, cost savings and quality gains. By aligning with JEFE HEX, we’re strengthening our ability to do just that. We look forward to working with our distributor channel and end-users to bring these new drilling/hole-making solutions to life in the shop floor. Welcome JEFE HEX to the Factory Link Inc. family!

Founded in 1960 by Gerhart Sowa Sr., Sowa Tool & Machine was built on a lifelong commitment to manufacturing excellence. Over a 75-year career in manufacturing, Gerhart Sowa Sr.—who passed away in 2025—laid the foundation for what would become a truly unique manufacturing organization. Today, Sowa Tool & Machine stands apart as the only manufacturer capable of delivering complete manufacturing solutions from spindle to table. With precision manufacturing and purpose-built product lines from trusted in-house brands like GS Tooling, Sowa provides U.S. manufacturers with the tools, accessories, and solutions needed to compete at the highest level. That legacy continues under the leadership of Gerhart Sowa Jr., who has advanced the company through improved designs, modernized manufacturing processes, and an unwavering focus on delivering best-in-class quality at a practical price. The result is a product portfolio engineered for performance, reliability, and real-world manufacturing demands. FactoryLink is proud to represent and support a partner whose legacy is built on precision, innovation, and manufacturing excellence—yesterday, today, and for generations to come. Click here and ask us about SOWA Tool & Machine!