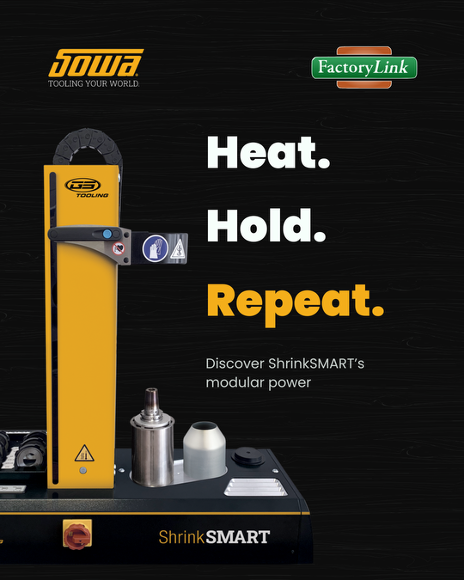

ShrinkSMART

Where Precision Meets Performance

In a world where every micron matters, precision tool holding isn't just a nice-to-have — it's essential. That’s why Sowa Tooling developed the ShrinkSMART system: a high-performance shrink-fit solution engineered to meet the demands of today’s most exacting machining environments.

What is ShrinkSMART?

ShrinkSMART is a thermal shrink-fit tool holding system that utilizes heat expansion to mount tools with exceptional grip strength and precision. Once cooled, the tool holder clamps the cutting tool with micron-level accuracy — ensuring optimal rigidity and eliminating runout-related inconsistencies. Whether you're tackling intricate aerospace components, high-speed milling operations, or tight-tolerance mold cavities, Shrink Smart brings confidence and consistency to your spindle.

Key Benefits

- Extreme Clamping Force: The shrink-fit interface eliminates tool slippage, delivering rock-solid grip in demanding operations.

- Superior Runout Accuracy: With less than 3μm of runout, expect longer tool life, better surface finishes, and improved part quality.

- High-Speed Ready: Balanced for speeds up to 25,000 RPM, Shrink Smart is ideal for high-speed spindles and aggressive cutting strategies.

- Slim Nose Design: Designed for maximum accessibility in deep cavities and narrow pockets.

- Quick & Repeatable Setup: Compatible with standard shrink units, the installation process is fast, clean, and reliable.

- Exceptional Value for Price: While we always lead with quality, it's worth noting—ShrinkSMART delivers premium performance at one of the lowest price points in the market. You get the best of both worlds: top-tier performance without the premium cost.

- All-Inclusive Standard Features: Unlike many competitors who upsell essential capabilities as costly add-ons, ShrinkSMART comes fully equipped. Many features that are optional (and expensive) elsewhere come standard with the Sowa Tool machine—saving you time, money, and hassle.

- Modular Flexibility & Future-Proofing: The ShrinkSMART is designed with scalability in mind. Start with the essentials and add on later—all on the same platform. Many competitor machines restrict you to specific models that limit your upgrade options. With Sowa Tool, you're investing in a solution that grows with you.

Built for Precision Industries

ShrinkSMART is trusted by manufacturers in aerospace, medical device, die/mold, and precision engineering — any application where performance, balance, and tool life are non-negotiable. From setup to spindle, it’s engineered to help you machine smarter.

Contact one of our Regional Managers for more information!