Updates from NexGen Tooling LLC

A message from:

Mike Shea

Director of Product Development & Applications, NexGen Tooling LLC

Mobile: 207-719-5837

mshea@nexgentooling.com

July 8, 2024

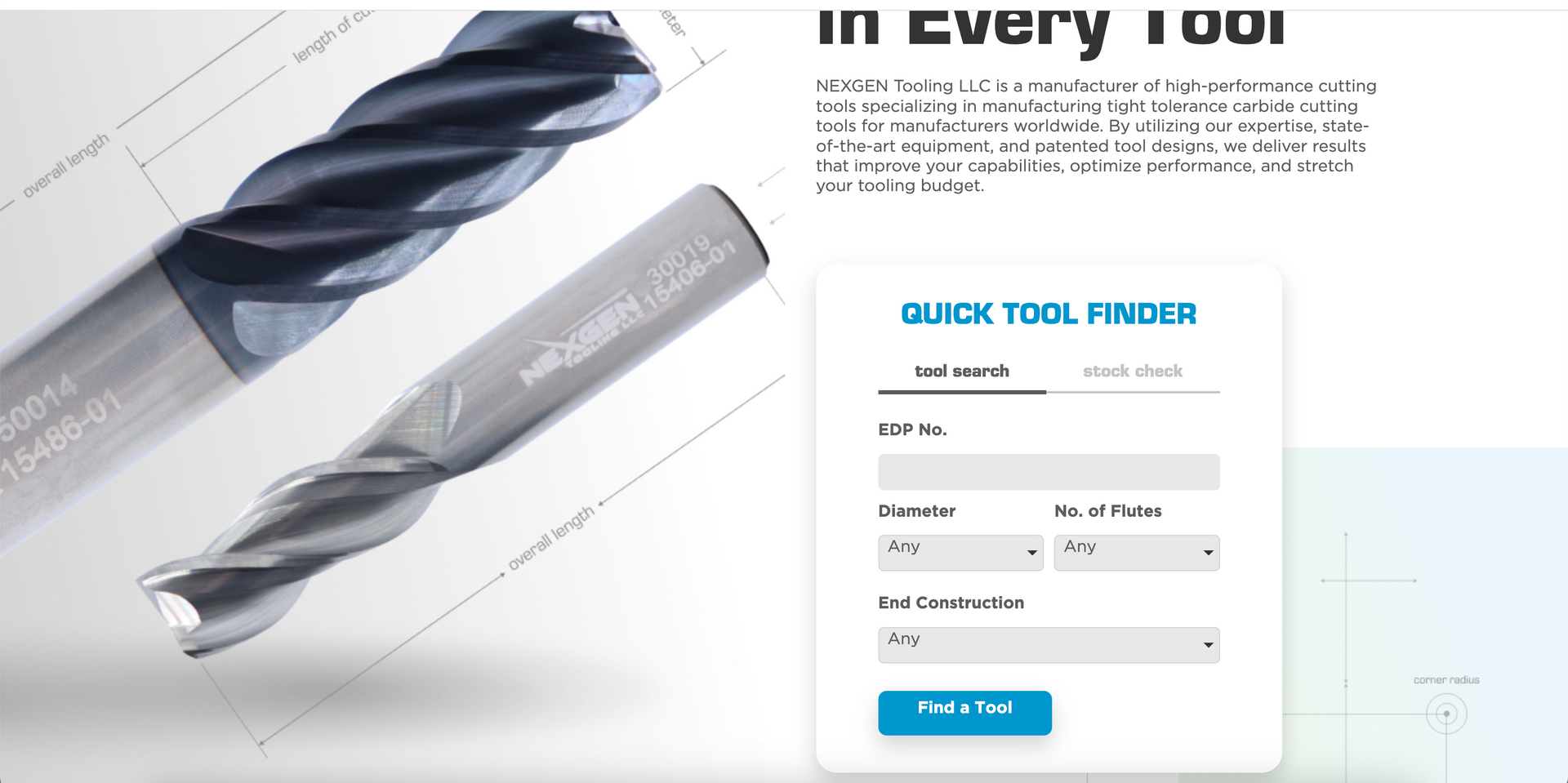

We have updated our website www.nexgentooling.com to include all the new additions to our 2024 High Performance Product Catalog, including our new 3 Flute Variable Pitch End Mills for Non-Ferrous Materials, and our new 3, 4 & 5 Flute Reduced Neck End Mills. We have also updated the search function on the website to include an EDP search to easily find List Price & Availability.

In an effort to get our Products into your hands in a more timely manner, we now ship packages 5 lbs & under via UPS Blue at Ground Rates on Orders with Prepaid & Add Freight. This applies to all Customers outside of the UPS Ground 2 Day Shipping Zone from our Office in Springvale, Maine.

We are growing! In the past 6 months we have added 3 new CNC Grinders and have acquired land & property adjacent to our Manufacturing Facility to use for future expansion. Our priority is to provide our High Performance Catalog Product off the shelf, and continue to offer 2-3 week delivery for coated specials.

For the first time, we will be exhibiting at IMTS September 9-14, 2024, please stop by Booth 431753 in the West Building! We would love to see you & show you how High Performance is all we know!