The Advantages of Ceramic End Mills: A Game-Changer in CNC Machining

Ceramic end mills have revolutionized the world of CNC machining, offering numerous advantages over traditional carbide and high speed steel end mills. Haydale’s SiC Whisker Reinforced Solid Ceramic End Mill offers the following Features & Benefits.

1. Heat Resistance:

Ceramic end mills are made from advanced ceramic materials that can withstand extreme temperatures without losing their strength or integrity. This heat resistance makes them ideal for machining difficult to cut materials like Inconel (and other high-temperature alloys), Hardened Steels (40+ HRC), and Cast & Ductile Irons.

2. Longer Tool Life:

Ceramic end mills are more wear-resistant than carbide or high-speed steel end mills, leading to longer tool life and reduced downtime for machining operations. This means less frequent tool changes and lower maintenance costs.

3. Improved Surface Finish:

Ceramic end mills produce smoother finishes, reducing the need for additional finishing steps. This not only saves time but also improves the overall quality of the final product.

4. Chemical Inertness:

Ceramic end mills are chemically inert, making them ideal for machining materials that are sensitive to corrosion or contamination. This includes medical implants, aerospace components, and other critical applications.

5. Low Vibration:

Ceramic end mills generate less vibration during machining, resulting in improved surface finishes and reduced tool wear. This makes them ideal for precision machining operations.

6. Environmentally Friendly:

Ceramic end mills are made from advanced ceramic materials that are more environmentally friendly than traditional carbide or high-speed steel end mills. This makes them a sustainable choice for manufacturers looking to reduce their environmental footprint.

7. Cost-Effective:

While ceramic end mills may be more expensive than traditional end mills, their longer tool life and improved performance can lead to cost savings in the long run. This is especially true for high-volume production.

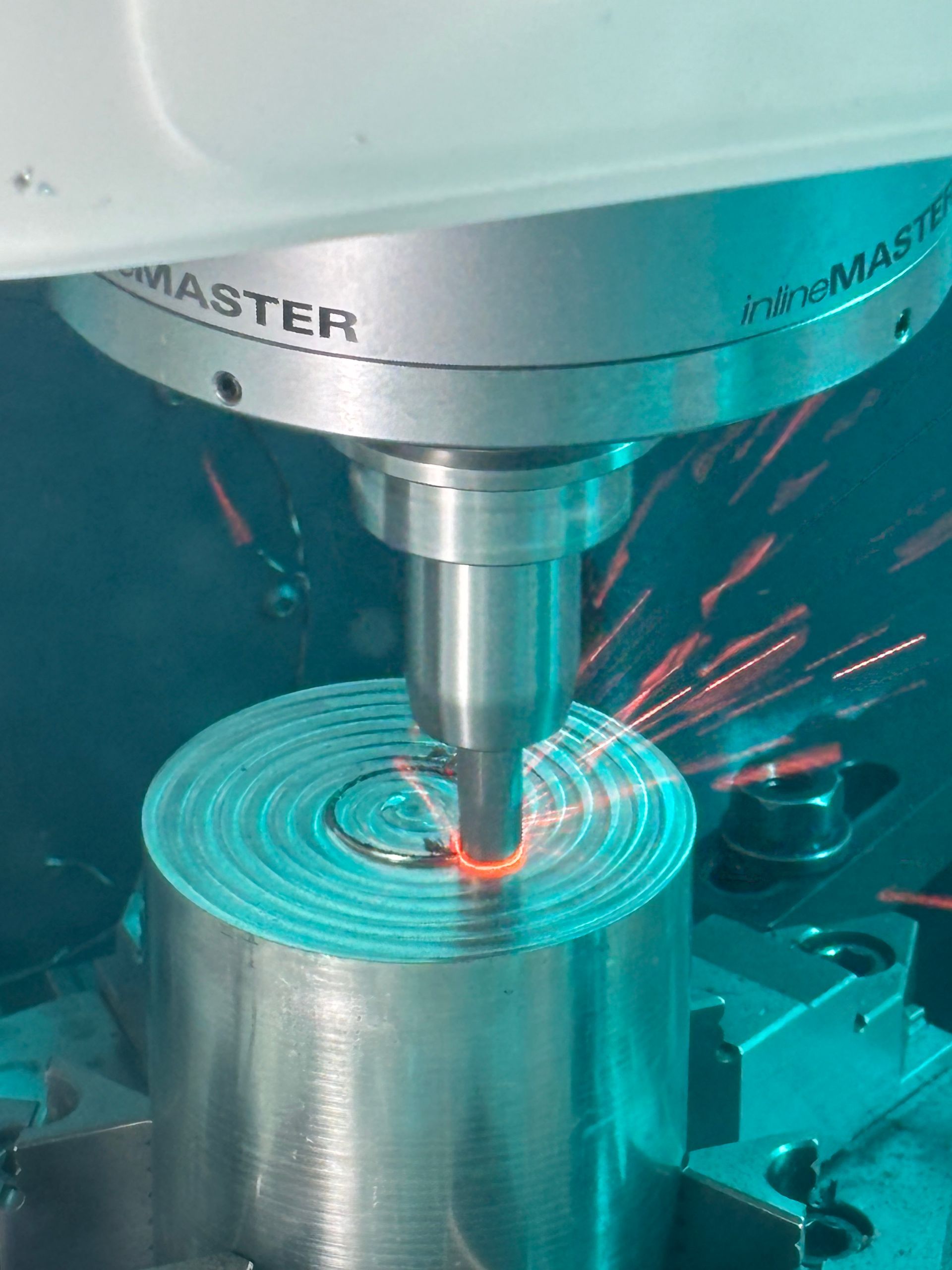

Check out Haydale's SiC Whisker Ceramic End Mill in the video below. 👇

Contact us at Silar@Haydale.com for more information, sample tools, pricing, and general inquiries.