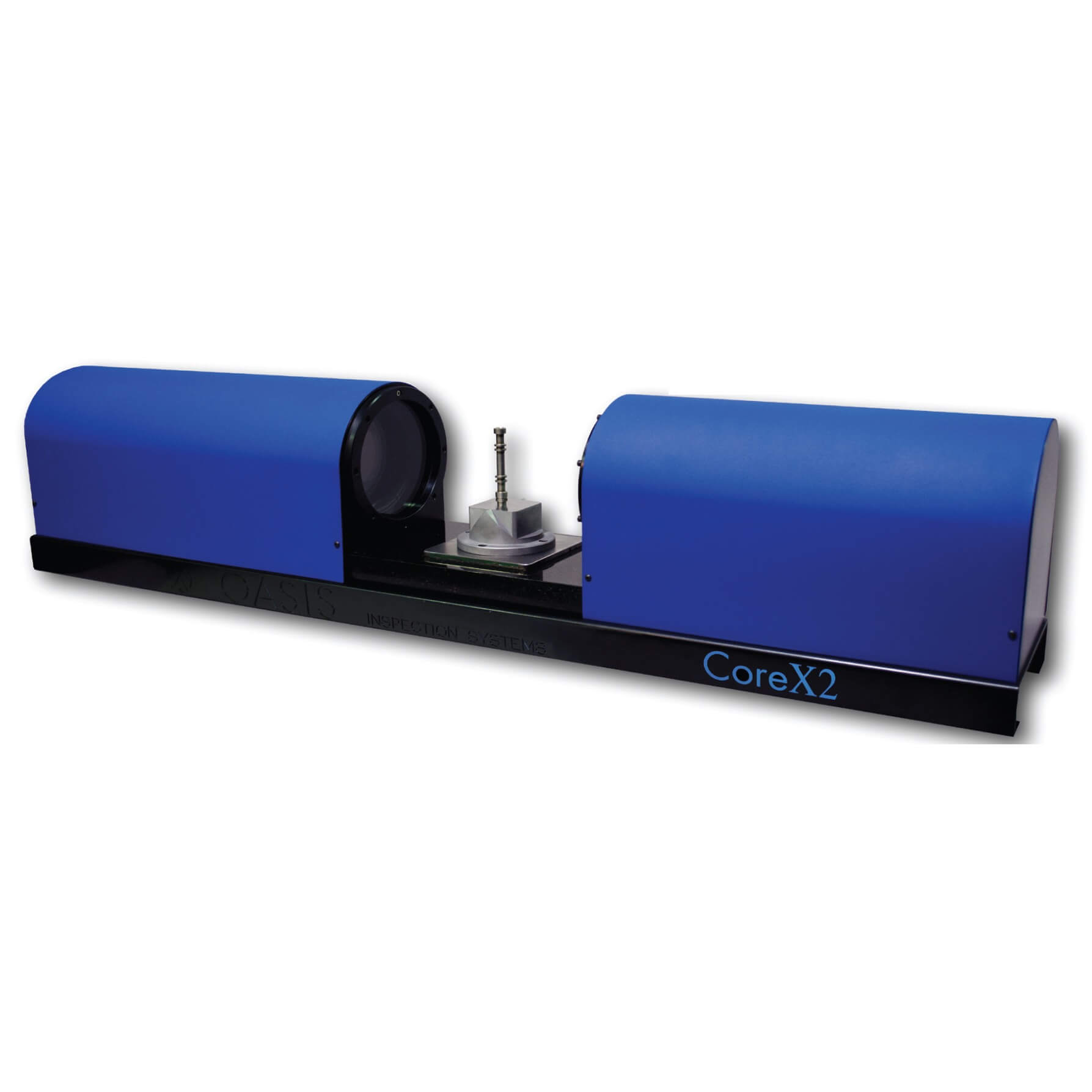

The Oasis CoreX2

Next-Level Precision in Non-Contact Measurement

At Factory Link Inc., we’re proud to represent solutions that help manufacturers achieve faster, more reliable, and more efficient results. One of the standout innovations in our metrology lineup is the Oasis CoreX2 — a non-contact optical inspection system designed for today’s precision manufacturing needs.

What Is the Oasis CoreX2?

The Oasis CoreX2 is an advanced optical measurement system that provides instant dimensional inspection of turned, ground, milled, and threaded parts. Engineered for speed and accuracy, it’s built to handle the increasing demand for real-time measurement right on the production floor.

Key Features & Benefits

✔ Dual Optical Systems: The CoreX2 uses two cameras to measure complex parts in one pass, capturing both length and diameter features simultaneously.

✔ Ultra-Fast Measurement: Provides full part inspection in just seconds, reducing downtime and enabling true in-process control.

✔ Non-Contact Precision: Eliminates operator influence, ensuring repeatability and accuracy across every shift.

✔ User-Friendly Software: The intuitive OASIS software allows for quick setup, real-time pass/fail feedback, and automatic data recording for traceability.

✔ Shop-Floor Ready: Built tough for production environments, the CoreX2 makes high-precision measurement as easy as pushing a button.

Why It Matters for Manufacturers

With tighter tolerances and faster cycle times becoming the norm, traditional measurement methods like micrometers and calipers can slow down production and introduce variability. The CoreX2 solves these challenges by delivering:

- Increased throughput by cutting inspection time from minutes to seconds.

- Improved quality control with consistent, automated measurements.

- Reduced scrap and rework thanks to real-time process adjustments.

- Full data traceability for audits, certifications, and customer reports.

Applications

The Oasis CoreX2 is ideal for manufacturers producing high-precision components across industries such as:

- Medical devices

- Aerospace

- Automotive

- Defense

- Precision machining and contract manufacturing

As your representative for Oasis Inspection Systems, Factory Link Inc. provides local support, training, and integration guidance to ensure you get the most from your CoreX2 investment. Our team works side-by-side with manufacturers to maximize efficiency, accuracy, and profitability on the shop floor.

The Oasis CoreX2 is more than a measurement system — it’s a productivity tool that helps manufacturers save time, cut costs, and deliver with confidence.

Contact us for more information!