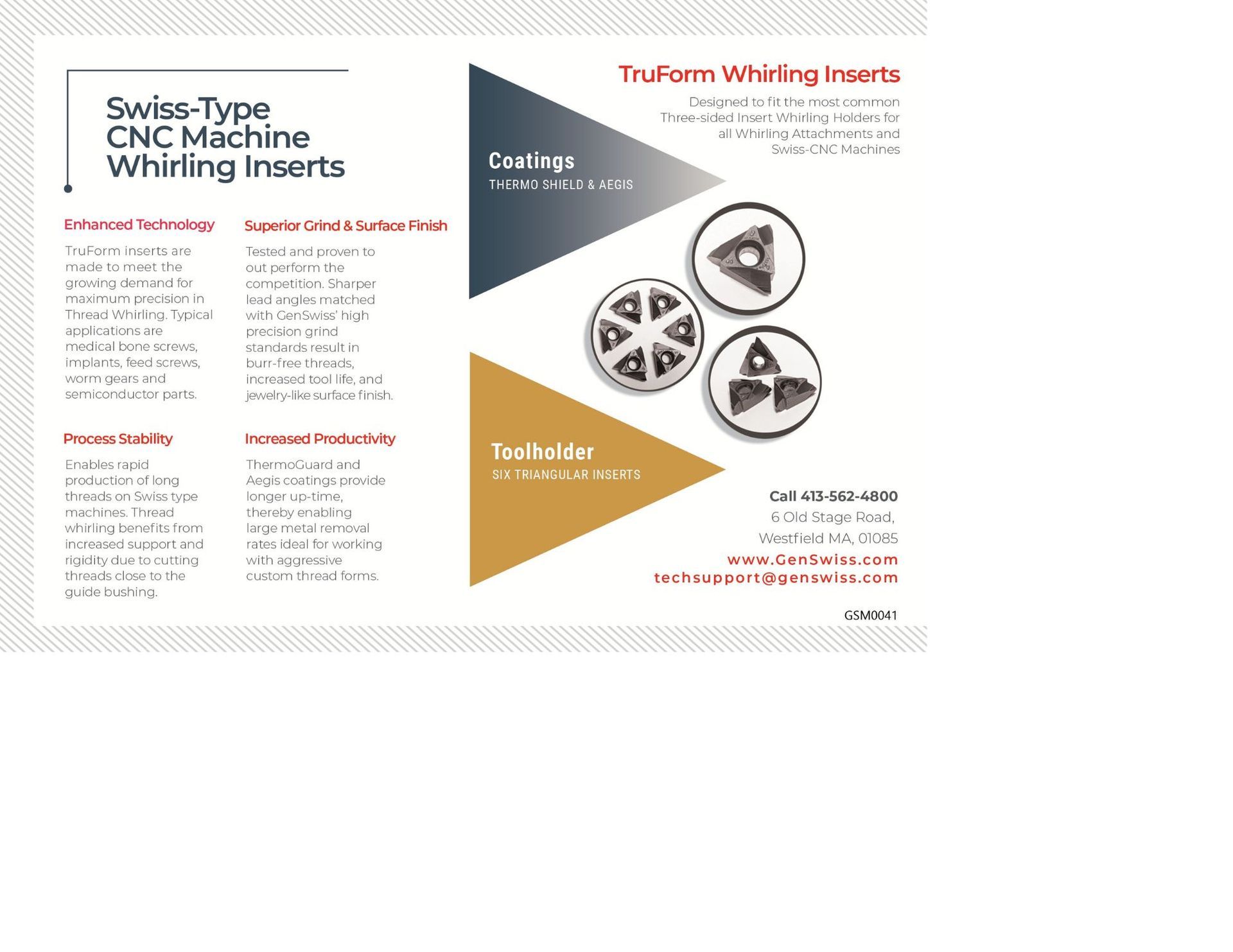

Genswiss TruForm Whirling Inserts

New TruForm Whirling Inserts:

Designed to fit the most common Three-sided Insert Whirling Holders for all Whirling Attachments and Swiss-CNC Machines

Enhanced Technology

TruForm inserts are made to meet the growing demand for maximum precision in Thread Whirling. Typical applications are medical bone screws, implants, feed screws, worm gears and semiconductor parts.

Process Stability

Enables rapid production of long threads on Swiss type machines. Thread whirling benefits from increased support and rigidity due to cutting threads close to the guide bushing.

Superior Grind & Surface Finish

Tested and proven to out perform the competition. Sharper lead angles matched with GenSwiss' high precision grind standards result in

burr-free threads, increased tool life, and jewelry-like surface finish.

Increased Productivity

ThermoGuard and Aegis coatings provide longer up-time, thereby enabling

large metal removal rates ideal for working with aggressive custom thread forms.

Custom profile inserts available.