Precision at the Core

Precision at the Core

When it comes to machining, precision and reliability are non-negotiable. That’s why Factory Link Inc. is proud to represent Sowa Tool Holders, a trusted name in tool holding solutions for shops across North America.

Why Tool Holders Matter

A high-performance tool holder is more than just an accessory — it’s the critical link between your spindle and your cutting tool. Poor tool holding can lead to vibration, runout, reduced tool life, and inconsistent part quality. Sowa addresses these challenges head-on, giving manufacturers the stability and accuracy they need to stay competitive.

The Sowa Advantage

- Unmatched Accuracy – Engineered for minimal runout, ensuring repeatable, precise machining.

- Rigorous Quality Standards – Manufactured to meet and exceed industry tolerances for lasting performance.

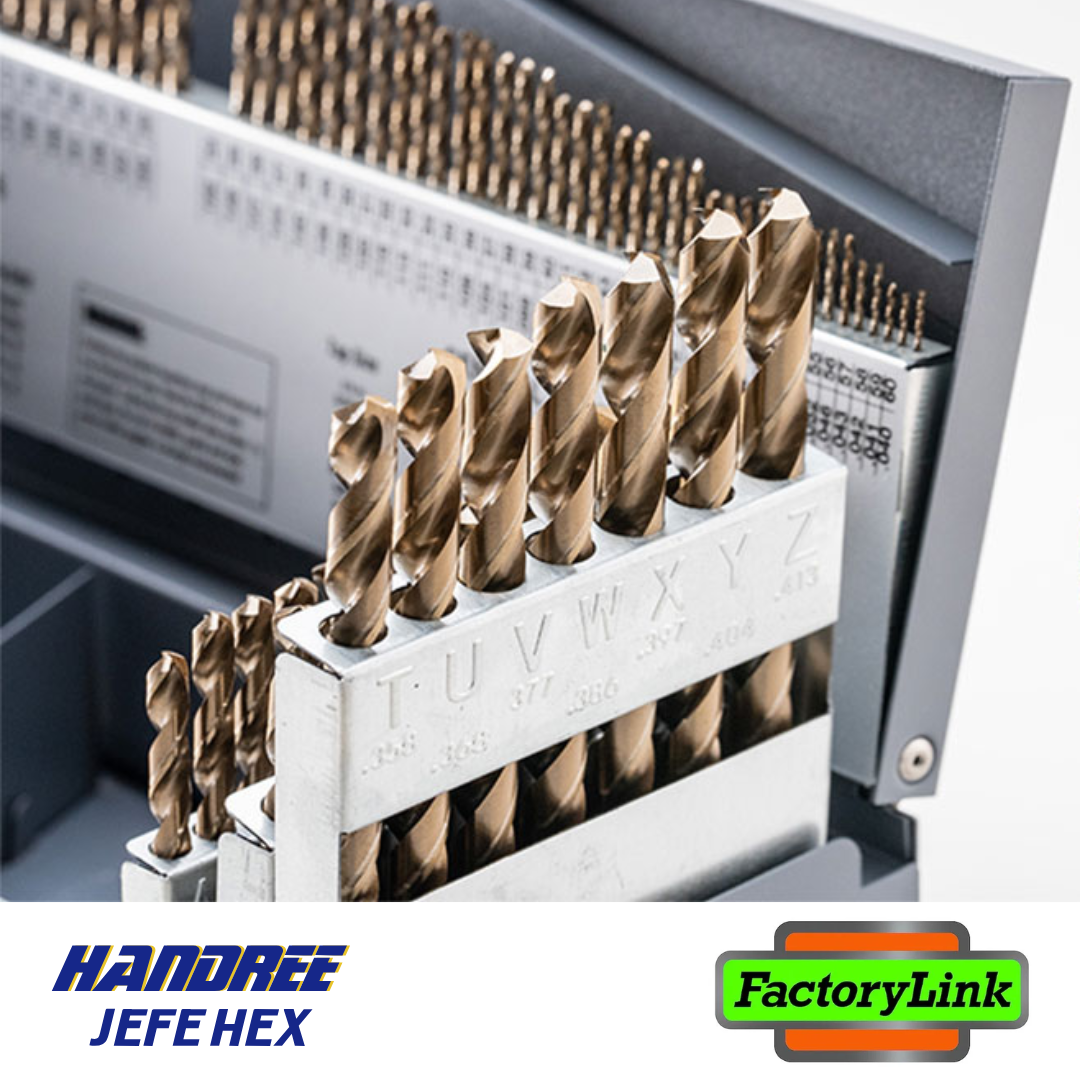

- Versatility – From ER collet chucks and end mill holders to shrink-fit and high-performance options, Sowa offers solutions for a wide range of machines and applications.

- Value Without Compromise – Competitive pricing makes Sowa a go-to brand for shops looking to balance quality and cost.

Factory Link Inc. + Sowa: Delivering More Than Products

As your local Factory Link Inc. representative, we don’t just supply tool holders — we provide application-driven recommendations to help you maximize uptime, extend tool life, and improve finishes. Whether you’re running high-speed milling, heavy roughing, or precision drilling, Sowa has the right solution — and we’ll help you implement it.

At Factory Link Inc., we stand behind our mantra: Delivering Solutions, Not Just Products. And with Sowa Tool Holders, that promise becomes reality on the shop floor.