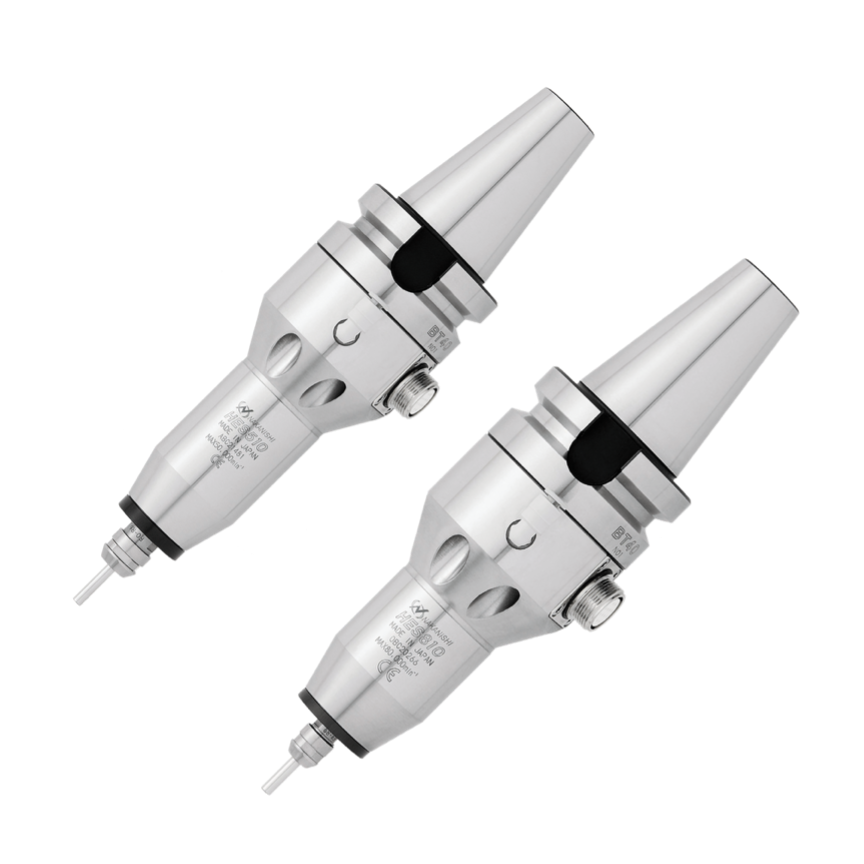

Enhance Your Machining Capabilities with NSK's HES510 & HES810 High-Speed Electric Spindles

NSK's HES510 & HES810 High-Speed Electric Spindles

In the realm of precision machining, achieving high-speed operations without compromising accuracy is paramount. NSK's HES510 and HES810 high-speed electric spindles offer a solution that integrates seamlessly with existing equipment, elevating performance without the need for extensive modifications.

Unlocking High-Speed Precision

The HES series spindles are engineered to transform conventional milling machines and machining centers into high-speed machining powerhouses. By enabling operations such as small diameter drilling and milling, these spindles deliver exceptional surface finishes and precision.

Key Features

- HES510:

- Speed Range: 5,000–50,000 RPM

- Maximum Output Power: 340W (0.45HP)

- Spindle Accuracy: Within 1 µm

- Ideal for small-diameter drilling and milling

- Compatible with various tapers including BT, CAT, NT, HSK, and R8

- HES810:

- Speed Range: 20,000–80,000 RPM

- Maximum Output Power: 350W

- Spindle Accuracy: Within 1 µm

- Designed for ultra-precision high-speed milling

- Supports various tapers such as BT, CAT, NT, HSK, and ST32

One of the standout advantages of the HES series is the ease of integration. These spindles can be mounted on existing equipment, allowing for a broader range of operations without the need for significant equipment overhauls. The one-piece motor and spindle construction ensures smooth rotation and durability, while the air-cooling system maintains optimal operating temperatures.

Implementing the HES series spindles has shown tangible benefits in various applications. For instance, integrating the HES510 spindle into a machining process reduced cycle times by up to 75%, enhanced torque, and maintained consistent RPMs, leading to improved efficiency and product quality.

NSK's HES510 and HES810 high-speed electric spindles represent a significant advancement in machining technology. By facilitating high-speed, high-precision operations on existing equipment, they offer a cost-effective solution to meet the evolving demands of precision manufacturing.

For more information and to explore the full range of HES series spindles contact us at techsupport@factorylink.com.