FactoryLink Friday Microdrilling by GMauvais USA

FactoryLink Friday Microdrilling by GMauvais USA

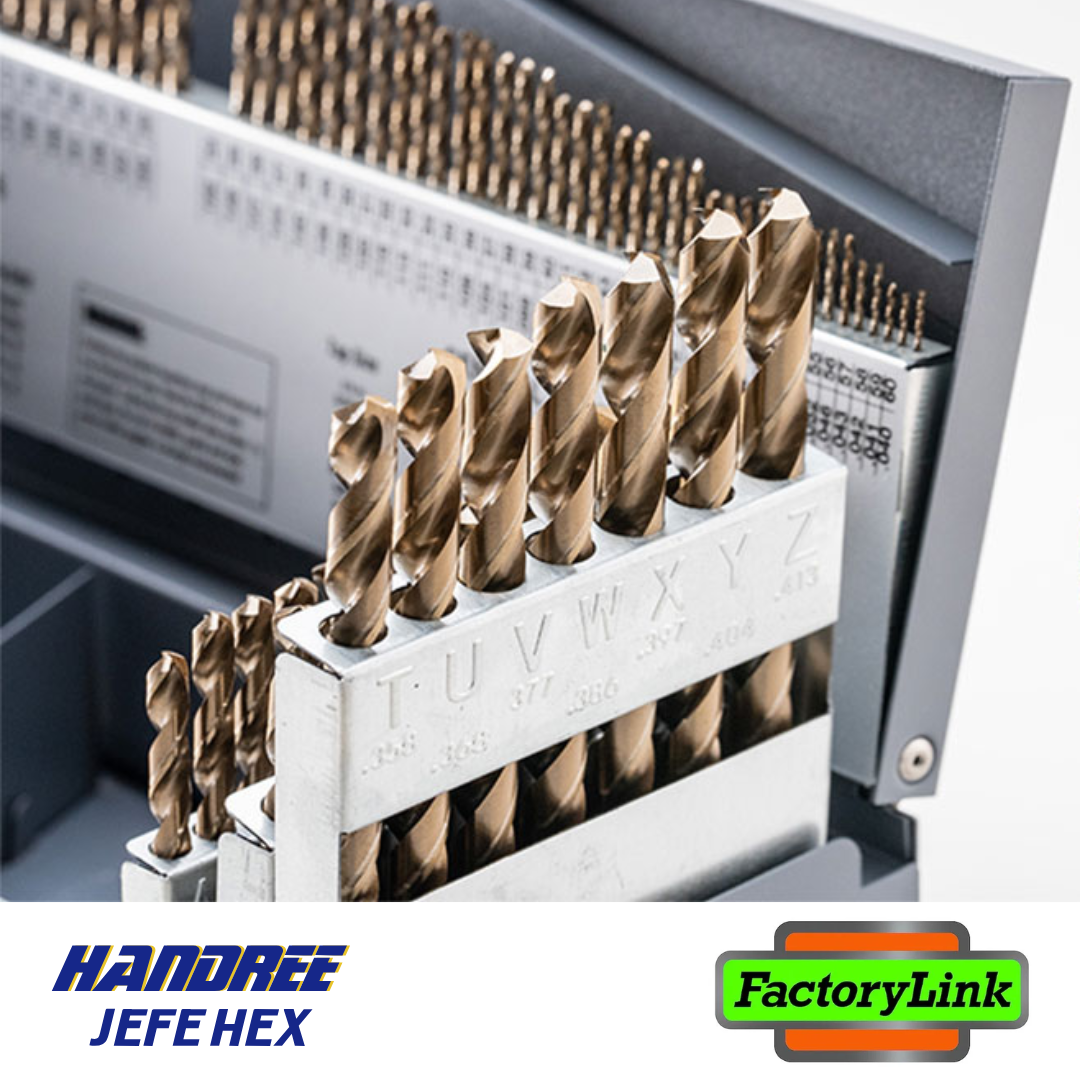

Pilot Precision Products offers a comprehensive range of high-precision micro drills under the GMauvaisUSA™ brand, renowned for their exceptional accuracy and quality. These micro drills are meticulously engineered to achieve concentricity, circularity, and straightness within 2 microns, ensuring consistent performance and repeatability in critical applications.

Key Features:

- Unmatched Precision: Each drill is manufactured to maintain dimensional tolerances of h6, h4, and h3 µm, providing superior edge quality and ultra-fine surface finishes.

- Material Excellence: Utilizing high-speed steel with 8% cobalt (HSS-E) and 10% cobalt micro-grain carbide, these drills offer enhanced heat resistance and extended tool life.

- Versatile Applications: Suitable for a wide array of industries, including medical, dental, electronics, automotive, aerospace, watchmaking, jewelry, and precision instrumentation

Product Series:

- HSS-E Cobalt Series: 5100 and 5140 Series.

- Solid Carbide Series: 6100, 6120, 6130, and 6140 Series.

- High-Performance Series: 6200 HP and 6220 HP Series.

- Coolant-Thru Series: 6230 CT Series.

- Specialty Drills: 1100 Series Half Round Gun Drills, 3100 and 3200 Series 3-Flute Drills, 62FLX Series, and 62H1 Single Flute Helicoidal Drills.

Pilot Precision also offers customization options, delivering tailored micro drill solutions with specific length-to-diameter ratios within a four-week lead time.

For more information and to explore the full range of micro drills ask Eddie Krall our technical support specialist at ekrall@factorylink.com / 260-460-0051.